Apron Systems

BNP Associates, Inc. has developed a team to address the need for a concise grouping of professionals dedicated to the design of Apron Systems.

Our focus is aimed at the following:

Passenger Loading Bridges Pre-Conditioned Air 400 Hz Ground Power Visual Docking Guidance Systems (VDGS) Potable Water Aircraft Parking

Design

Baseline aircraft parking plan alternatives are developed for the projected fleet mix, including GSE parking and vehicle service lanes. As necessary, several alternatives are also considered to optimize the various evaluation criteria including aircraft fleet mix, gate/aircraft interchangeability, passenger loading distributions, etc.

The passenger loading bridge generalities are also developed including approximate PBB tunnel lengths, range of aircraft servicing needs, maximum slopes and facility interface coordination. Point-of-use versus centralized 400 Hz and PC air studies are developed as well as Potable Water requirements. VDGS system layout and the interface to the Passenger Boarding Bridges are also developed when they are a requirement of the project.

The design process concludes with estimating, scheduling and recommendations of the apron systems configuration which best meet the needs of the client. BNP uses the AviPlan software program for its aircraft parking, servicing and layout designs. This is combined with an extensive library of standard CADD symbols and design standards.

Specifications

Preparation of bidding documents for the procurement of the various apron systems. Project specific requirements are included in our standard, proven specifications. BNP Specification packages are divided so multiple contractors can be included in the equipment procurement. Our specifications include distinct sections for the PBB, PC Air, 400 Hz, Potable water and VDGS.

Bidding & Award Assistance

Pre-qualification of vendors, release for bid packages, pre-bid conferences, bid review and contract negotiations. BNP knows the strengths, weaknesses and has first-hand knowledge of production capacities and capabilities of all the various manufacturers.

Construction Administration

BNP provides as part of our Construction Administration role, coordination of the engineering and manufacturing processes, Factory Acceptance Testing, coordinate both construction staging and construction around on-going operations. We also provide supervision of the installation, punch listing, equipment acceptance testing and Aircraft Gate Fit testing if required.

BNP brings the proven expertise that provides cost and operationally effective solutions to our clients. The process had been a missing element in the industry where the planning of these critical systems was often left to less experienced personnel or to the equipment manufacturers.

Baggage Handling

BNP brings an extensive background of experience with the planning, design and implementation of airport Baggage Handling Systems and have been providing specialized consulting services to the air transportation industry on a worldwide basis since 1971. In our more than 45 years of professional experience, BNP has been involved in hundreds of projects throughout the world and our continuous industry exposure keep us fully appraised of current and planned industry requirements.

Our consulting services include Master Planning, Facility Design, Baggage Handling System Design, Project Management and Construction Administration. BNP are a dedicated group of professionals, widely experienced in airline and airport requirements for the handling of baggage. In meeting the needs of our clients, BNP provides:

System Evaluation Design Specifications Cost Analysis Construction Management and Administration

BNP’s approach is that we take a project from its inception through to operational support to include:

Statistical Analysis

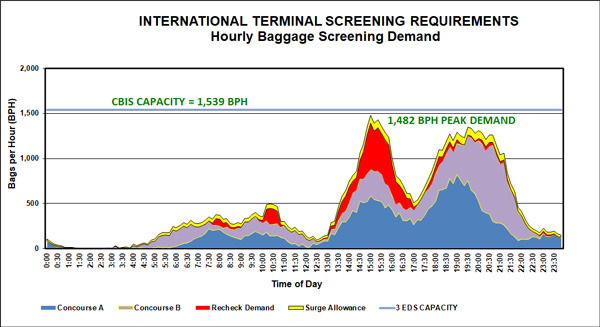

Analyzing the current and future needs of the system using numerous computer models that have been developed by our analysis and simulation engineers. The resulting data is imported and integrated into the BNP developed simulation model along with the system design drawings, data reported by the simulations is then transformed into meaningful charts and statistically valid reports for the Airport/Airline to validate the functionality of the proposed design.

Design

Development of conceptual and designs are based on considering various levels of automation, which are then measured against the economic and operational the projects definition document. The design is coordinated with the A&E teams to ensure the system is an integral component of the facility. BNP performs the majority of the design work with BIM utilizing the Revit platform.

Contract Documentation

Functional detailed specifications and contract documents are prepared based on the system configuration, the design objectives and BNP’s practical real world history of mechanical, electrical and controls components and products.

Bidding & Award Assistance

Pre-qualification of vendors, release of bid documents, assistance in bid evaluation process all of which is especially beneficial to our clients given BNP’s knowledge of the industry, market pricing and contract requirements.

Construction Administration

BNP’s participation in the construction management/administration process includes submittal reviews, program management, and site supervision; scheduling, detailed inspections of the system, acceptance testing and assistance to the client in the operational start up period.

To successfully provide the project, BNP works very closely and collaboratively with the Airport, the Architectural and MEP design team members and the User Airlines, resulting in openness to share ideas and concepts on how to best serve the airlines/airport’s evolving requirements while responding to the project requirements.

Cargo Handling Systems

BNP Associates, Inc. has designed and implemented some of the largest and most complex Air Cargo Systems in the world including Hong Kong, Singapore and Doha. Our services include Master Planning, Facility Design, Cargo System Designs and Project Management. We are a dedicated group of professionals, widely experienced in the airline and airport requirements for the handling of cargo. Meeting the needs of our clients, BNP provides:

System Requirements

Determination of Requirements and Constraints, Development of Broad Concept of Operations, Concept Design, Evaluation and Recommendation of Preferred Concept.

Specifications

Preparation of technical performance specifications to include General Requirements, Definition of scope of work of the system of the supplier, Definition of operational equipment requirements.

Construction Management

BNP provides construction management/administration process including submittal reviews, program management, and site supervision.

Analysis

BNP will develop the requirements and constraints for the Cargo System in terms of resources (airside interface positions, storage positions, workstations, truck docks, etc.) based on the detailed forecast provided by the Client. This will include requirements for special storage areas, storage for oversize cargo, empty ULD Storage, sorter systems for parcels and small packages. With this information, a proposed Concept of Operations will be developed. This is the most significant part of analysis and the concept design study and involves the highest levels of expertise, creativity and engineering acumen.

Design

BNP, for the client review develop a group of concepts in 2D, representing broad topics such as various terminal shapes, single vs multi-level facility, exterior airside interfaces vs interior airside interface aisles, and different operational concepts, etc. The preferred design will include 3D space planning of the Cargo functions to determine the anticipated height of the facility and includes 3D equipment to allow validation of the quantities required versus the provisions in the design. Based on the preferred design BNP will provide rough order magnitude costs and implementation schedules.

Simulation

The preferred concept will be developed by BNP into a 3D dynamic discrete event simulation model where the flow of each ULD and each ASRS load unit is modeled. The simulation will be based upon the peak time processing and include the processing of cargo incorporating security and customs requirements. Manual processes (e.g. ULD buildup, forklift movement, Dolly train movement) will be modeled with representative process times coordinated with the client.

Construction Documentation

BNP will prepare and provide functional detailed specifications, drawings and contract documents based on the cargo system configuration, the client approved design objectives and BNP’s practical real world history of mechanical, electrical and controls components and products.

Bidding and Award Assistance

Pre-qualification of vendors, release of bid documents, assistance in bid evaluation process all of which is especially beneficial to our clients given BNP’s knowledge of the cargo industry, market pricing and contract requirements.

Construction Administration

BNP’s participation in the construction management/administration process includes submittal reviews to include structural loading drawings, building interface drawings and maintenance access drawings. Assist in the preparation of and attend the execution of factory acceptance tests.

Program management, and site supervision, scheduling, detailed inspections of the system, acceptance testing and assistance to the client in the operational start up period.

BNP brings proven expertise in Cargo System Design

and implementation that provides cost and operational effective solutions to our clients.

Simulation

BNP has been developing simulations for the baggage handling and air cargo industries since 1995. BNP’s simulation experience encompasses modeling of simple queuing systems to the largest airport baggage handling systems with over 20,000 individual conveyor sections/tracks. We have a core group of professionals dedicated to providing simulation services to the airport/airline industry. BNP uses simulation modeling tools such as AutoMod and Quest to build 3D models of each system. The simulation model control logic is written to closely represent actual PLC controls of conveyors and cargo systems.

These models are calibrated and validated to ensure that they accurately represent real-world operations. In addition to being world leaders in AutoMod and Quest simulations, we have broad skills in integrating AutoMod/Quest with other applications. We have expertise in SQL databases and Visual Basic combined with MS Excel. These skills are used to import data into the simulation model either at the start of a simulation run or interactively as it runs. BNP simulations can be integrated in real control or management systems to act as an emulation test bed. BNP’s simulation engineers are also skilled in VB, VBA, C# & C++ programming languages.

Demand Forcasting

As part of the BNP simulation/modeling process, detailed demand forecasts are developed to quantify the expected demand to the baggage and cargo systems. BNP documents all the key data and assumptions for the project and produce a Simulation Function Design Specifications (SimFDS) deliverable.

The SimFDS includes key data such as flight schedules, baggage and passenger characteristics, and operational characteristics as well as the Key Performance Indicators (KPIs) that will be used to evaluate the performance of each system. Once these planning assumptions are established, a demand forecast is produced, and initial system resource requirements are estimated.

3D Simulation Modeling of Baggage Handling Systems

These tools have been used to evaluate and assist in the design of over 50 baggage handling systems to include very large BHS and Cargo systems throughout the world and numerous systems in the USA (including TSA mandated checked baggage screening systems).

Through use of the these models, the projected demand to each component of the BHS (mainline, ICS loops, EBS storage areas, screening areas, make-ups, cargo systems etc.) can be quantified early in the process. Bottleneck areas with the system can be identified, and design and/or controls improvements can be evaluated. These models help to ensure that new commissioned systems will operate efficiently, and provide a means for identifying effective solutions to existing systems without having to experiment with making changes to a live system.

3D Simulation Modeling of Passenger Facilities

BNP also uses its simulation capabilities to model passenger flow including evaluating design of passenger checkpoint facilities and circulation in public spaces such as check-in areas and bag claim halls.

3D Simulation Modeling of Checkpoints

BNP has expanded it's simulation capabilities to include the modeling of passenger security checkpoints. This is becoming especially important in this day and age where significant improvements in automation and checkpoint design are being evaluated. The simulation tools allow for the realistic deployment of new technology in a virtual environment.

Energy Management

One of the specialized uses of BNP’s simulation models is to identify the potential energy savings that can be achieved by managing the run time of conveyors/components. Using VFDs, conveyors will only run while bags are approaching the conveyor.

Downstream conveyors are started three seconds prior to the bag physically reaching the charge-end of conveyor. After the last bag exits a conveyor, the conveyor turns off after a pre-set configurable delay varying from 1 to 600 seconds. Using modeling, the best strategies for powering the system can be refined and system energy consumption can be significantly reduced.

Deliverables

Deliverables to the airport/airline includes scenario reports documenting the function of the system under the various scenarios plus animations of the simulation runs showing baggage/cargo traveling through the system in 3D.

BNP provides the following:

• Simulation Functional Design Specification that defines general and project specific control functions of the simulation model.

• Full 3D simulation animations

• Simulation Reports that document the performance of all simulation scenarios